The principle of KNOOP hardness lays in the Vickers hardness testing method.

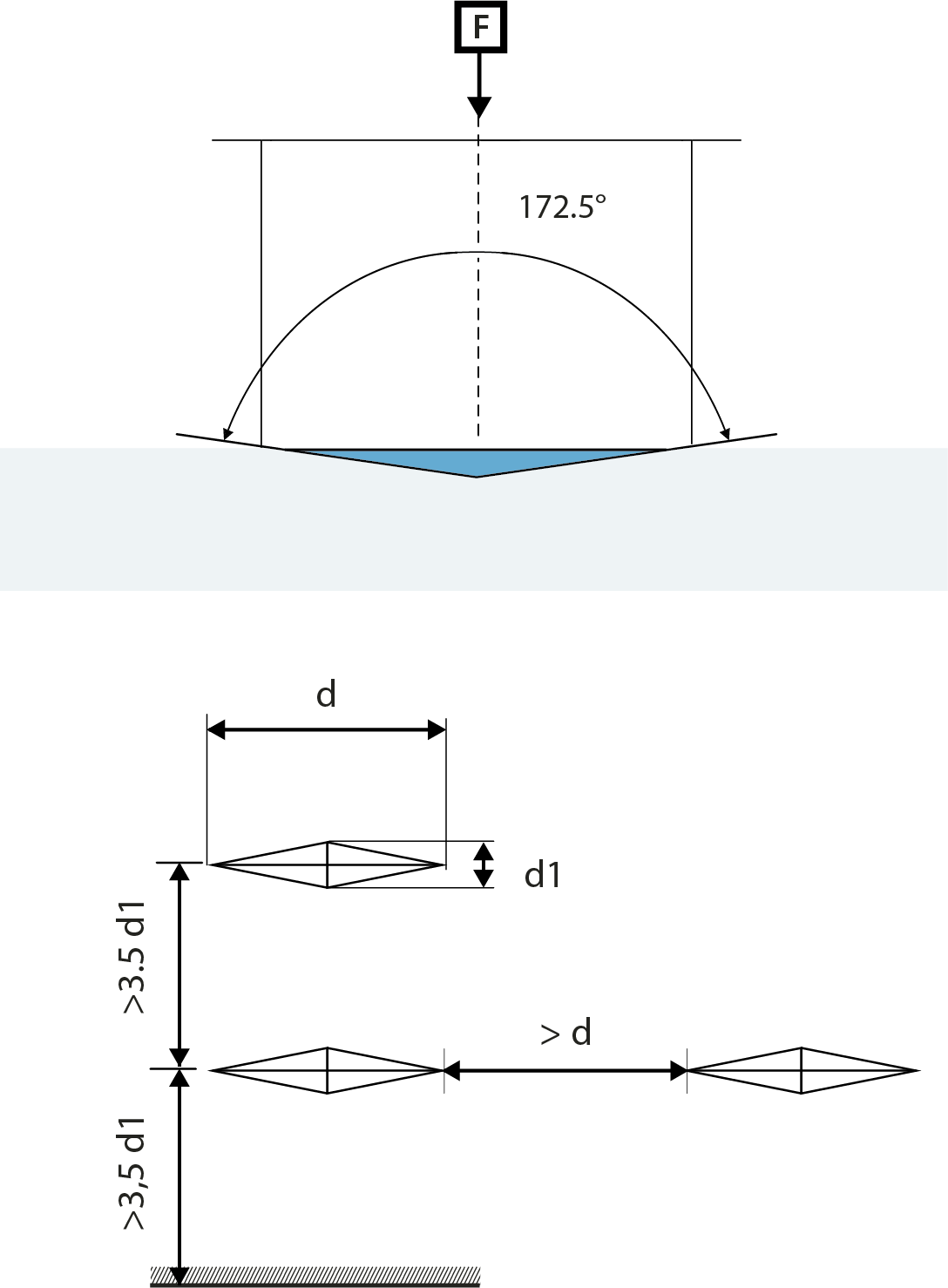

The Knoop diamond indenter has a significant difference between the long and short diagonals.

This shape is often better suited for determining variations of hardness over very small distances, edges of bushings, compared to the Vickers indenter. Also the angle of the diamond tip is different from a vickers diamond.

While the Knoop indenter resulting indentation is not symmetrical as the Vickers indention, it will also be subject to more variation of the resulting hardness values. This applies in particular to Knoop scales below 200gf.

Knoop hardness testing is not typically being used to define volume hardness testing, although at 500 gf, the ASTM standard provides conversions of Knoop numbers to other hardness test scales. Knoop tests are not commonly performed at test forces above 1000 gf while under particular circumstances and or materials may need higher forces like 2 and 5 kgf. Expect larger variations in results at these loads.

The specimen preparation procedure in removing preparation damage is of great influence on the test results; this becomes even more critical as the test force decreases.