The Vickers hardness test method, also referred to as a microhardness test method (ASTM E-384, E92 and ISO 6507), consists of indenting the test material with a diamond indenter. This indenter has the form of a pyramid...

Read moreThe Rockwell hardness test method, as defined in ISO 6508 & ASTM E-18, is the most commonly used method around the world to determine a material’s hardness and is suitable for almost all metals and to some degree for plastics...

Read moreThe Brinell hardness test method (as defined in ASTM E10 and ISO 6506) is mostly used for heavy casted materials such as cast iron, aluminun or steel. Although Brinell loads can be found ranging from 1kgf to 3000kgf, most ...

Read moreThe Knoop resulting indentation is not symmetrical as Vickers indentions and will be subject to more variations of the resulting hardness values when testing to Knoop scales, especially below 200gf. Knoop hardness is normally not being...

Read moreUPI Laboratories Europe BV manufactures and provides calibrations of hardness testing related test blocks and indenters that meet and exceed the requirements of the global standards for indirect hardness testing calibration. UPI Laboratories confirms the physical requirements, but also the method and the procedures of how calibration values have been found. The final results are confirmed in the hardness test blocks or indenters corresponding certificates.

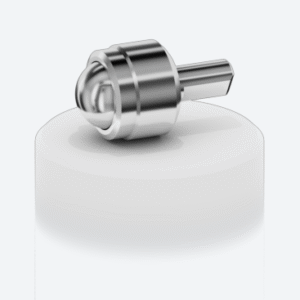

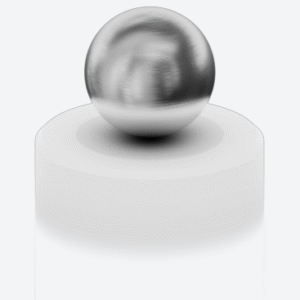

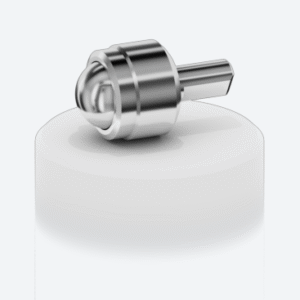

The range includes ball & diamond indenters for Brinell, Vickers, Micro-Vickers, Knoop, Rockwell and other ball indentation. Further we provide a wide range of high grade quality polished & excellent homogeneous hardness testing reference blocks.

All hardness test blocks and indenters are calibrated according to the requirements of the relevant ISO & ASTM standards. UPI Laboratories Europe BV is accredited as an ISO 17025 laboratory by the RvA (Board of Accreditation) in the Netherlands

UKAS, COFRAC, DAkkS and the RvA are members of the European Co-operation for Accreditation (EA) and are all signatories to the EA Multilateral Agreement (MLA) also including NVLAP & A2LA and are members of ILAC, Mutual Recognition Arrangements (MRA) for the members recognition of calibration certificates.